If you’ve ever wondered how mounting of network equipment works, you’re not alone. It’s a complicated process that can be difficult to understand, but some key components should be understood before you begin the project. So here are the basics: Rails, Bolts, Cage nuts, and Threaded holes.

Rails

Most servers are rack-mountable and come with a rail mounting option. These rails run the full depth of the rack and give the server additional stability. While some professionals prefer to use rails for everything, they are unnecessary for every server. Instead, they are typically used for servers that are heavier and larger.

Bolts

There are several different types of bolts for mounting network equipment. Typically, they’re sized to fit a rack’s front and rear posts. They’re also usually adjustable in depth, which makes installation easier. In addition, some types have several different thread types.

Cage Nuts

Cage nuts are used to secure network equipment to a rack. They fit into a square hole in the rack to hold threaded screws in place. Cage nuts are easy to install and remove. In addition, they are inexpensive, making them a practical choice for network and equipment racks. There are several cage nuts, but the most common and versatile are the 12-24 and the M6.

Cage nuts are used on server racks with square mounting holes. They prevent tapped holes from becoming stripped due to intermittent thread changes. They are available in three common sizes, allowing you to mount specialized equipment. However, they can be difficult to remove. If you have trouble removing cage nuts, consider using a Cage Nut Removal Tool to make the process easier.

Threaded Holes in Racks

Racks that feature threaded holes for mounting network equipment are generally more flexible and durable than those that do not. This type of mounting is also compatible with most rack types. Some racks feature a single central mounting hole, and some have multiple nested mounting holes. Those who want to be more flexible and customize their racks can consider a combination of both types of mounting.

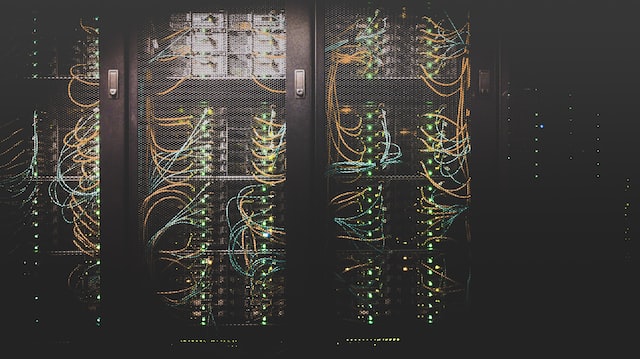

Before mounting a device, a person should make sure that all the cables are well-placed and properly connected to the device. In addition, they should remove any stray cables before mounting the device. Ensure that the cage nuts are inserted into the sockets on the rack, and mark the threaded holes in the rack with tape. In addition to threaded holes, there are also horizontal rails, which can be used to mount many servers.

Slides

When it comes to installing and mounting network equipment, there are several different options. Some equipment is slid in and out of the mounting surface. Other equipment is mounted using rails, usually adjustable and bolted to the front and rear posts. This allows the equipment to be supported by four posts and is simple to install.

Center-Mounting

You might want to consider center mounting if your network equipment requires multiple mounting positions. This method attaches hardware brackets at the center of the rack and has multiple benefits. For example, it centralizes weight distribution and lessens the pressure on the rack. Additionally, it improves balance. However, center-mounting is not recommended for equipment that uses batteries.

Screws

Screws for mounting network equipment are commonly used in networking racks. The choice of the correct screws depends on the type of rack enclosure you use. For example, square hole racks use cage nuts, while round hole racks use 1032-tapped screws. Most 2-post open relay racks use a combination of nuts and cage screws.

There are two common sizes of screws for mounting network equipment: 10/32 and 12-24. Both have different thread diameters and are used for mounting different equipment. For racks with holes that lack threads, you should use clip nuts. These nuts fit the specific screw type and can easily be changed to another screw type if necessary.